I have a drawer type under-counter refrigerator that has a wonky PCB. I would normally by now have just given up and ordered a new replacement, but apparently the manufacturer/supplier for this particular board was wiped out in the mainland Japan tsunami a few years ago. So the only option is to repair. There is a service that does repair/recondition for a fee, and I have already used them without success. Not even at all sure they did anything to my board at all, as all components look undisturbed.

Here's the wonky part — it works fine when it is not installed in the unit vertically. While it is laying in the floor behind the unit, the fridge works perfectly, albeit the power supply relay is more audible (louder click.) Once it is installed vertically in the slot that holds the housing, it starts cycling power every 2-3 minutes, and eventually starts timing out completely for 10 minutes or so at a time and then repeats the loop.

So amateur that I am, and after having great success with replacing bad caps and MOSFETs on a couple of power supplies using the DIYs on this forum, I am back again because I am solidly at my wit's end.

So here's the PCB:

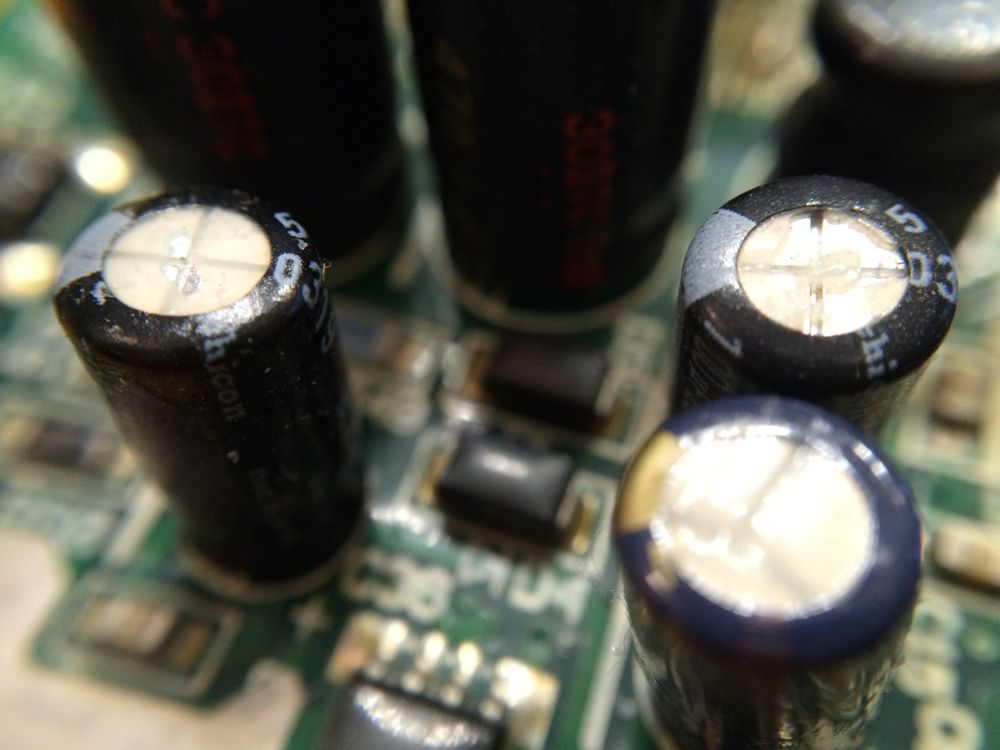

Another view, closeup of some of the caps:

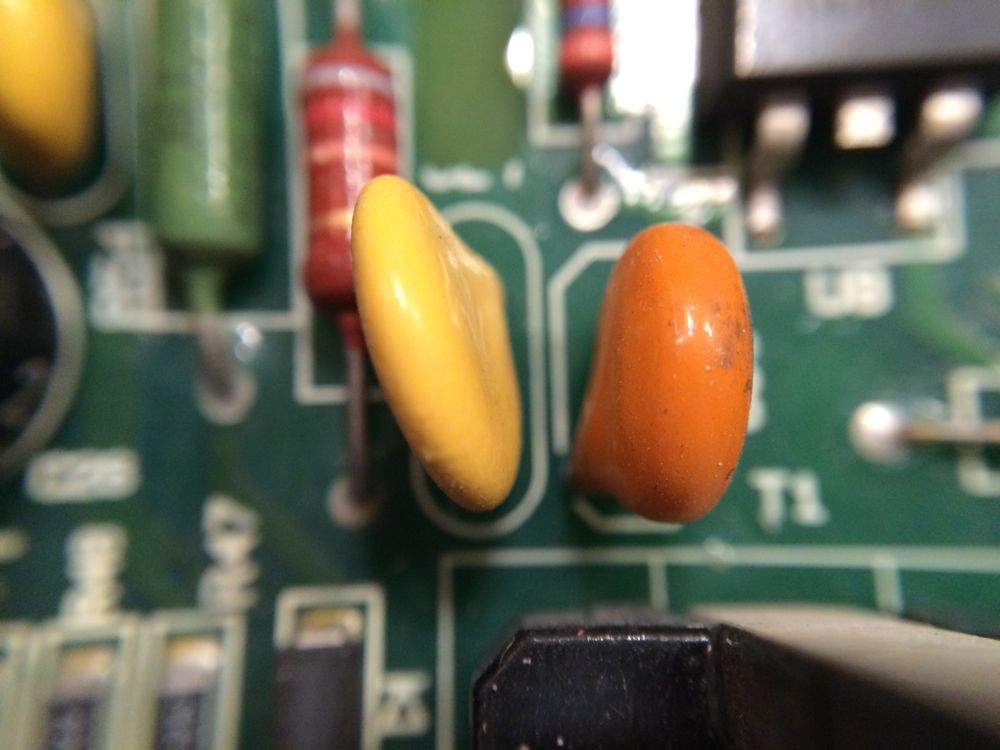

And this is how it sits horizontally on the floor and works:

There is a thermal fuse that attaches to the outside of the metal housing, which I thought may be suspect, but even when left unattached and dangling away from housing when the board assembly is reinstalled, the cycle/timeout symptoms still occur

So my question... are there any component types on that PCB that might suddenly become hyper sensitive to orientation after years of normal operations?

I should add that I have examined as closely as I could with magnification the connectors and harness wires for stress breaks or any other kind of problem that might occur when they are manipulated into position for board installation. I did not see anything that looked amiss.

Here's the wonky part — it works fine when it is not installed in the unit vertically. While it is laying in the floor behind the unit, the fridge works perfectly, albeit the power supply relay is more audible (louder click.) Once it is installed vertically in the slot that holds the housing, it starts cycling power every 2-3 minutes, and eventually starts timing out completely for 10 minutes or so at a time and then repeats the loop.

So amateur that I am, and after having great success with replacing bad caps and MOSFETs on a couple of power supplies using the DIYs on this forum, I am back again because I am solidly at my wit's end.

So here's the PCB:

Another view, closeup of some of the caps:

And this is how it sits horizontally on the floor and works:

There is a thermal fuse that attaches to the outside of the metal housing, which I thought may be suspect, but even when left unattached and dangling away from housing when the board assembly is reinstalled, the cycle/timeout symptoms still occur

So my question... are there any component types on that PCB that might suddenly become hyper sensitive to orientation after years of normal operations?

I should add that I have examined as closely as I could with magnification the connectors and harness wires for stress breaks or any other kind of problem that might occur when they are manipulated into position for board installation. I did not see anything that looked amiss.

Comment