I'm building a Bench PSU for a buddy of mine. He is an Aerospace Engineer and has needed a good high-amperage power supply for some time now for his tinkering with small motors and such and also to power a programmable battery charger.

We went PSU hunting at UCSD and found a 1996, Made In USA (!) 300w ATX power supply out of an old server. According to a sticker on the case it belonged to NASA. I took it home and cracked it open. NCC, Marcon, and JPCE-TUR caps. Nidec fan.

I did a ton of wire snipping, wired up a switch for power, am currently working on a two-color LED to indicate power state (standby/power on). Today I am going to drill holes for the binding posts and give the case a sanding and blast of paint because it is rather old and has a fair amount of rust.

Here is my question to you guys: I have some engine enamel in a can type of stuff. Can I give the case a light coat and throw it in the oven to cure it? I have some clearcoat stuff too, is it necessary or is cured engine enamel enough? I want a strong, durable finish not something that's going to chip and look like shit in a year.

If curing engine enamel is the way to go how long should i let it cure and how what temperature?

We went PSU hunting at UCSD and found a 1996, Made In USA (!) 300w ATX power supply out of an old server. According to a sticker on the case it belonged to NASA. I took it home and cracked it open. NCC, Marcon, and JPCE-TUR caps. Nidec fan.

I did a ton of wire snipping, wired up a switch for power, am currently working on a two-color LED to indicate power state (standby/power on). Today I am going to drill holes for the binding posts and give the case a sanding and blast of paint because it is rather old and has a fair amount of rust.

Here is my question to you guys: I have some engine enamel in a can type of stuff. Can I give the case a light coat and throw it in the oven to cure it? I have some clearcoat stuff too, is it necessary or is cured engine enamel enough? I want a strong, durable finish not something that's going to chip and look like shit in a year.

If curing engine enamel is the way to go how long should i let it cure and how what temperature?

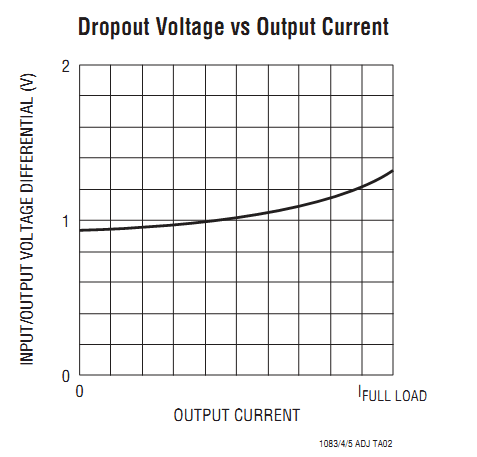

lt 1083:

lt 1083:

Comment