Hello everybody, i messed up this board i was in the middle of fixing

(we could also name this thread: "this is how NOT to do it")

top:

https://www.badcaps.net/forum/attach...id=16727&stc=1

https://www.badcaps.net/forum/attach...id=16728&stc=1

looks like my solder sucker sucked this time, dont blame it, my fault all the way, so i was wondering if anyone could help me out in this and point me to a good solution, cause i really am in the urge of fixing these &%&#)$)%&$ boards

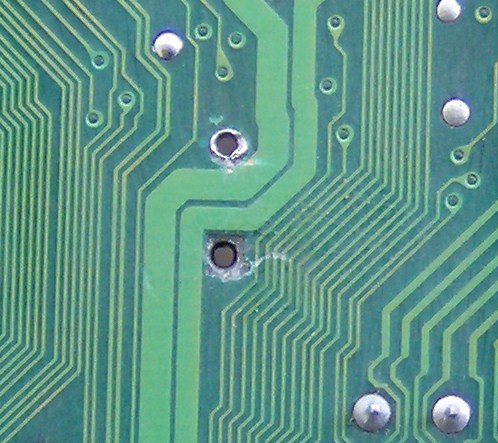

on the top i have tested for contuinity and still does it (among the positives and negatives of the three caps), the worst seems to me the positve on the cap of the side bottom part (first thread pic), -but the one in the middle also looks bad. (second pic)

https://www.badcaps.net/forum/attach...id=16731&stc=1

do you think that by the continuity kept on the top solder spots it should keep on working? or you think i should 'bridge' positive pin from those two caps to the third cap (i havent touched this third cause its a rubycon, it looks fine imo and its solder joints look fine) ? or u think i should just call it dead?

https://www.badcaps.net/forum/attach...id=16732&stc=1

https://www.badcaps.net/forum/attach...id=16733&stc=1

Any idea is welcome. and really appreciated.

ps. this is the https://www.badcaps.net/forum/showthread.php?t=10266 board thread ........

Thanks.

(we could also name this thread: "this is how NOT to do it")

top:

https://www.badcaps.net/forum/attach...id=16727&stc=1

https://www.badcaps.net/forum/attach...id=16728&stc=1

looks like my solder sucker sucked this time, dont blame it, my fault all the way, so i was wondering if anyone could help me out in this and point me to a good solution, cause i really am in the urge of fixing these &%&#)$)%&$ boards

on the top i have tested for contuinity and still does it (among the positives and negatives of the three caps), the worst seems to me the positve on the cap of the side bottom part (first thread pic), -but the one in the middle also looks bad. (second pic)

https://www.badcaps.net/forum/attach...id=16731&stc=1

do you think that by the continuity kept on the top solder spots it should keep on working? or you think i should 'bridge' positive pin from those two caps to the third cap (i havent touched this third cause its a rubycon, it looks fine imo and its solder joints look fine) ? or u think i should just call it dead?

https://www.badcaps.net/forum/attach...id=16732&stc=1

https://www.badcaps.net/forum/attach...id=16733&stc=1

Any idea is welcome. and really appreciated.

ps. this is the https://www.badcaps.net/forum/showthread.php?t=10266 board thread ........

Thanks.

i did some manual resoldering of certain areas, do you advise me to do it again? with more care? lemme update a little with pics, as of right now i have already cleaned it with iso, the board booted but close to the minute running mtest got stuck again. this time it just froze without weird characters showing. i tried to see if itd boot again and it did not, no POST, so i went to eat -bday- and came back and tested again and it booted, then i turned it off and is where i am right now, im gonna take pics so u can see the mess i did this time. last time on test: booting, but still gets stuck.

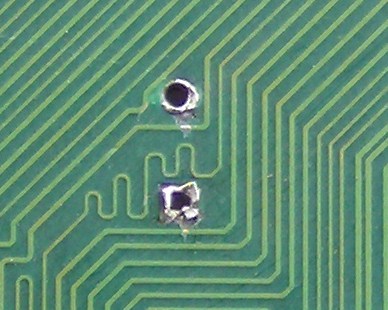

i did some manual resoldering of certain areas, do you advise me to do it again? with more care? lemme update a little with pics, as of right now i have already cleaned it with iso, the board booted but close to the minute running mtest got stuck again. this time it just froze without weird characters showing. i tried to see if itd boot again and it did not, no POST, so i went to eat -bday- and came back and tested again and it booted, then i turned it off and is where i am right now, im gonna take pics so u can see the mess i did this time. last time on test: booting, but still gets stuck. , this is how i managed to solder the mentioned area... i am sorry about my poor quality at work, i just have no excuse for that but the fact that i work under a lot of pressure

, this is how i managed to solder the mentioned area... i am sorry about my poor quality at work, i just have no excuse for that but the fact that i work under a lot of pressure

Comment