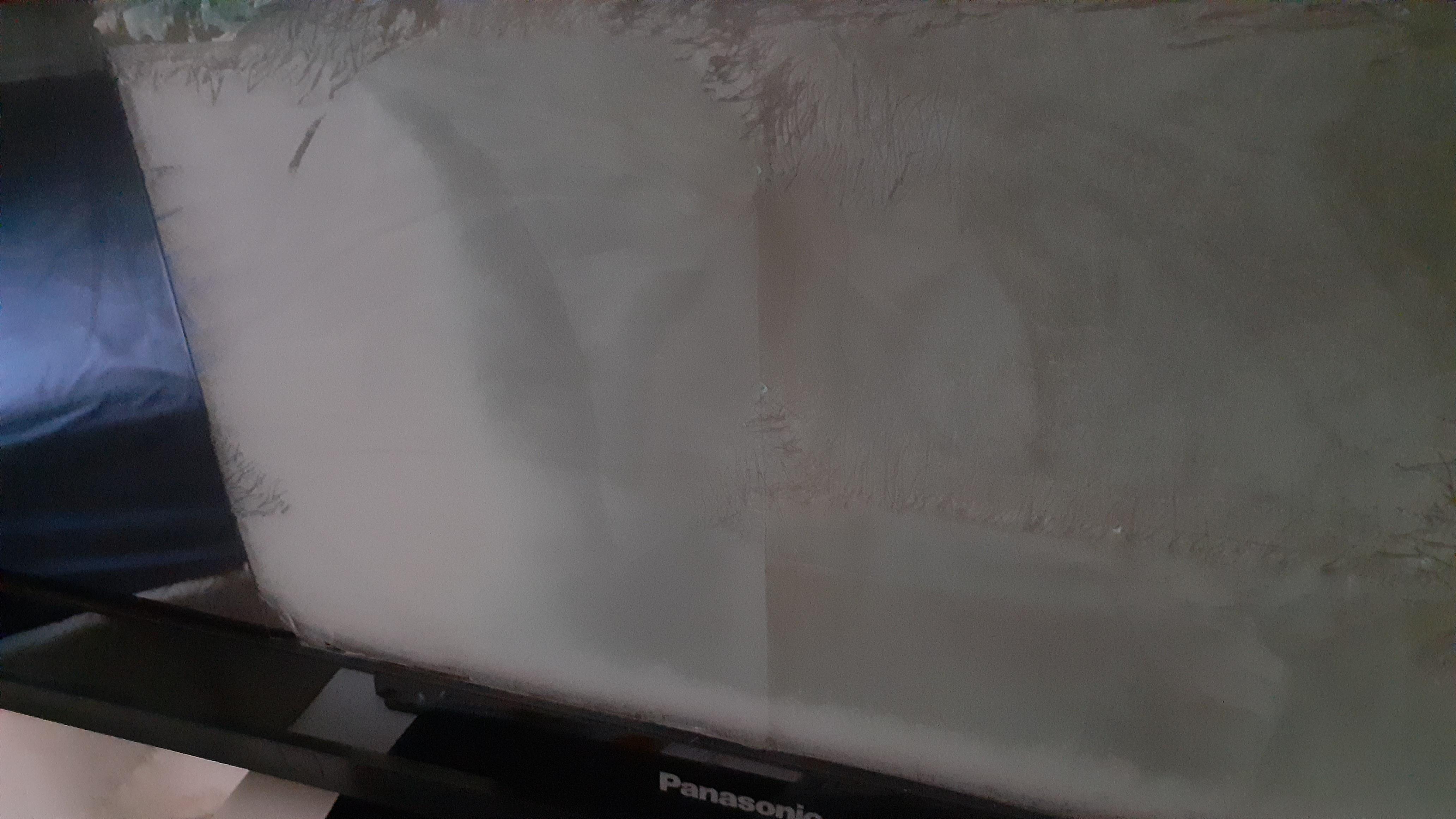

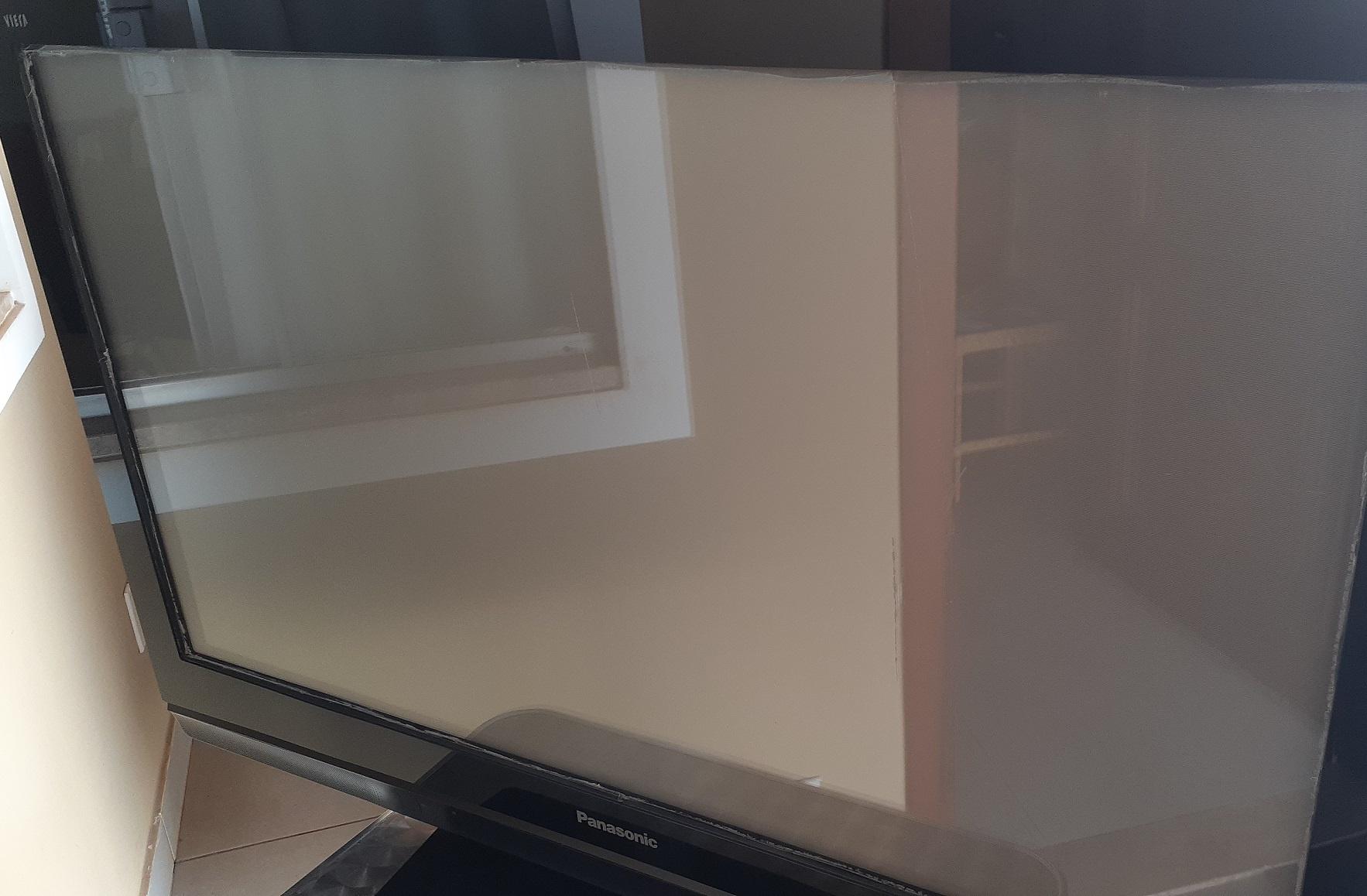

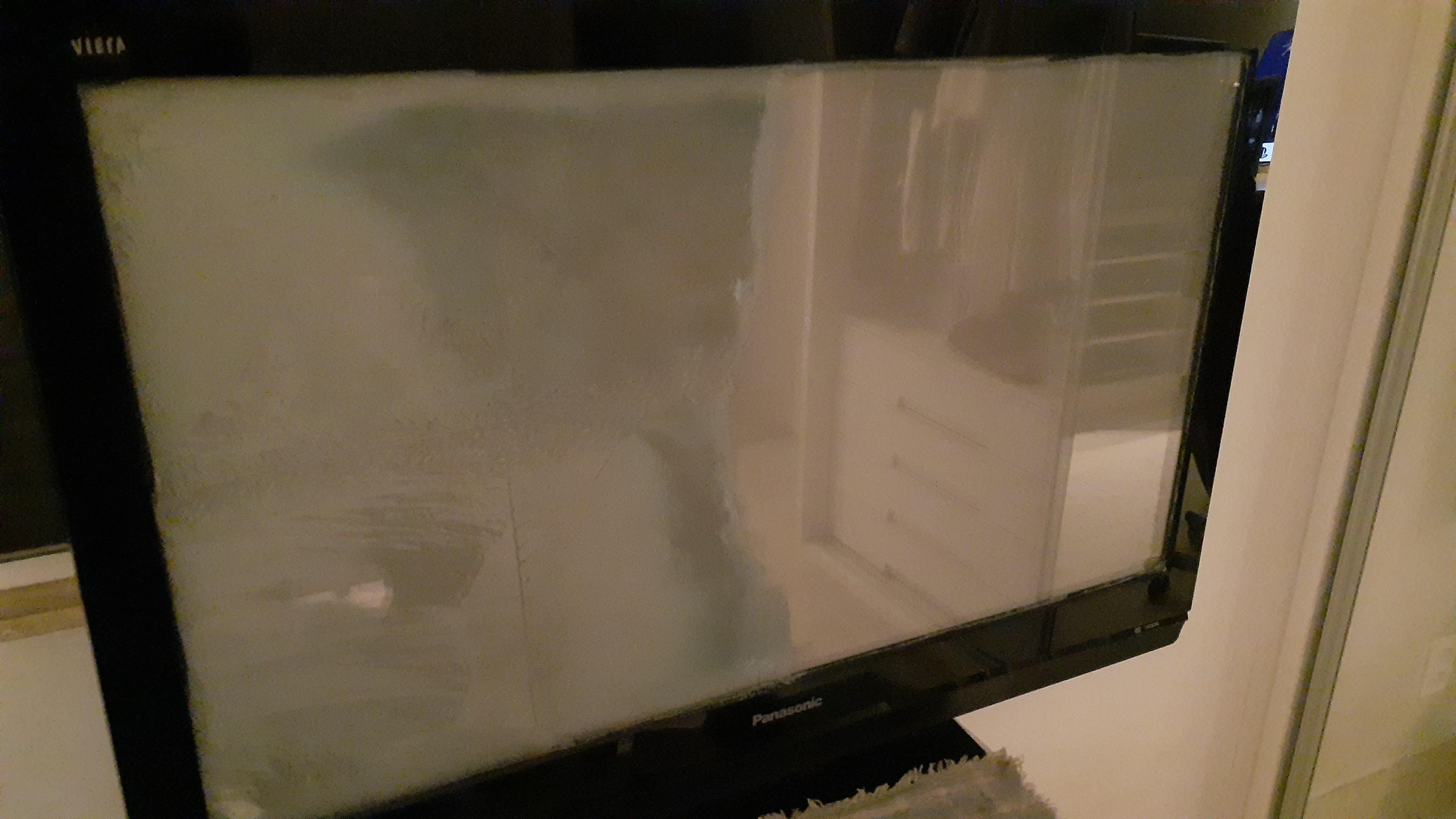

I got this set for very cheap, it works perfectly but the catch is that the protective coating was damaged. About 45% of the screen had a green tint, you can see exactly where the layer changed colors to a blueish tone (that actually makes everything green).

"Ok, that's probably just the anti-glare layer" - I thought. So using a microfiber cloth and automotive metal polish I was easily able to turn it into a nice mirror.

Unfortunately, the damage was beyond this layer and everything still had a horrible green tint. I initially wanted to completely remove the glass itself since it's not bonded to the PDP, but it had to stay due to potential structural issues.

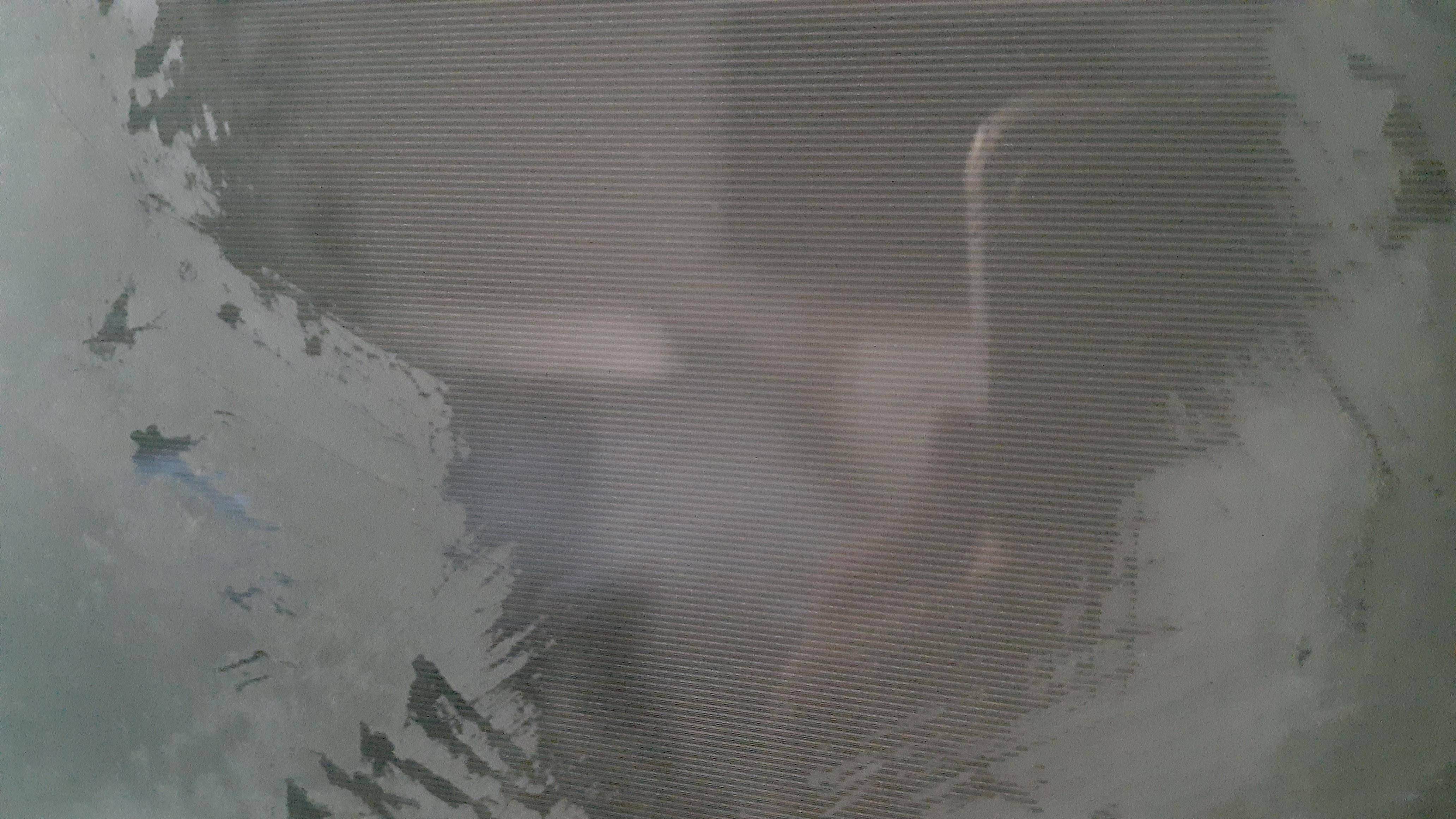

It was time to go all out, nothing to lose here anyways. I cut the Front Glass using a box cuter and realized there were more layers above the actual glass.

It's a simple task but requires tons of elbow grease, patience and ability.

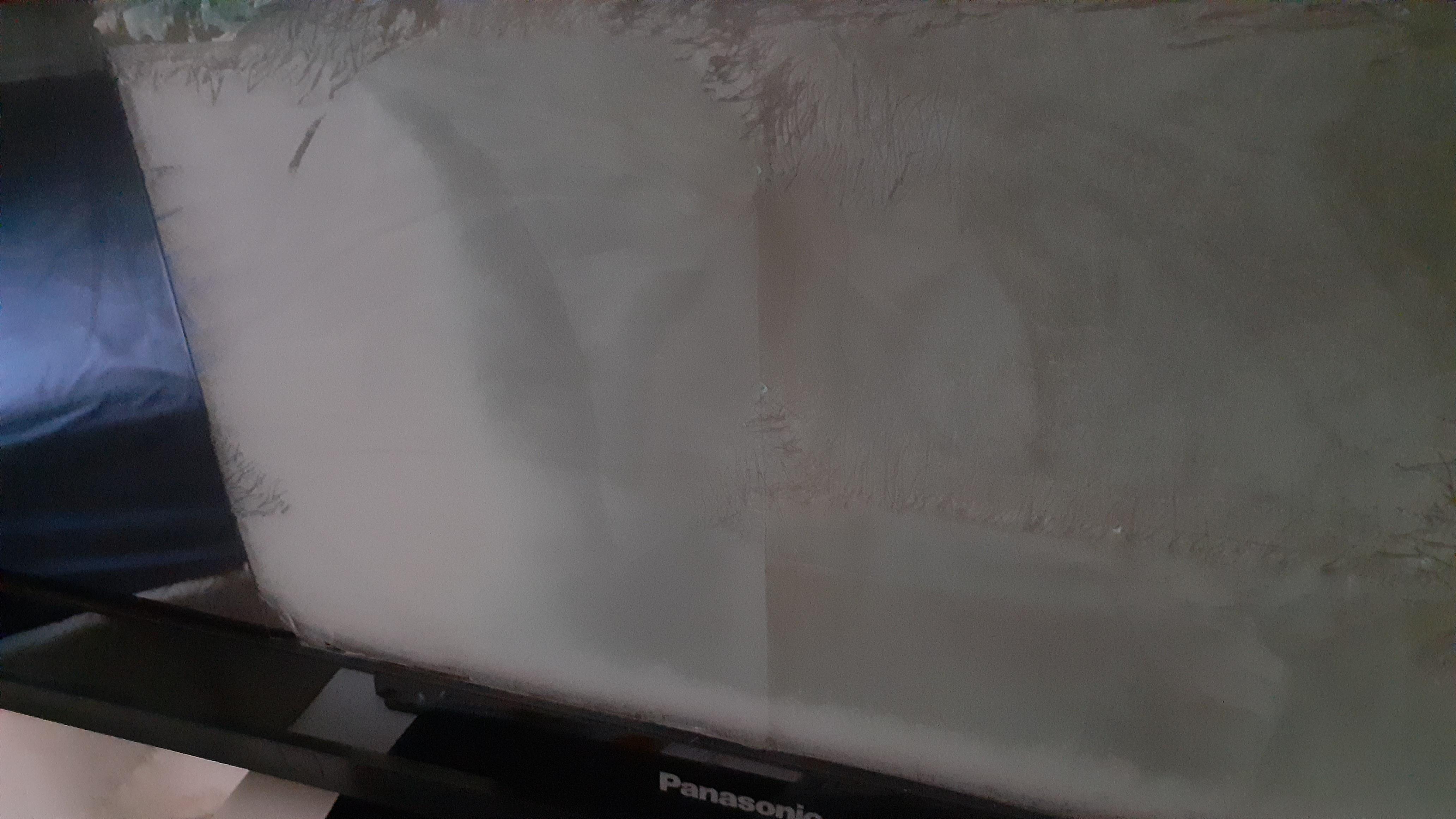

This is the tinted layer that enhances contrast/black levels and helps with colors, it's very similar to window tinted film. It comes out very easily.

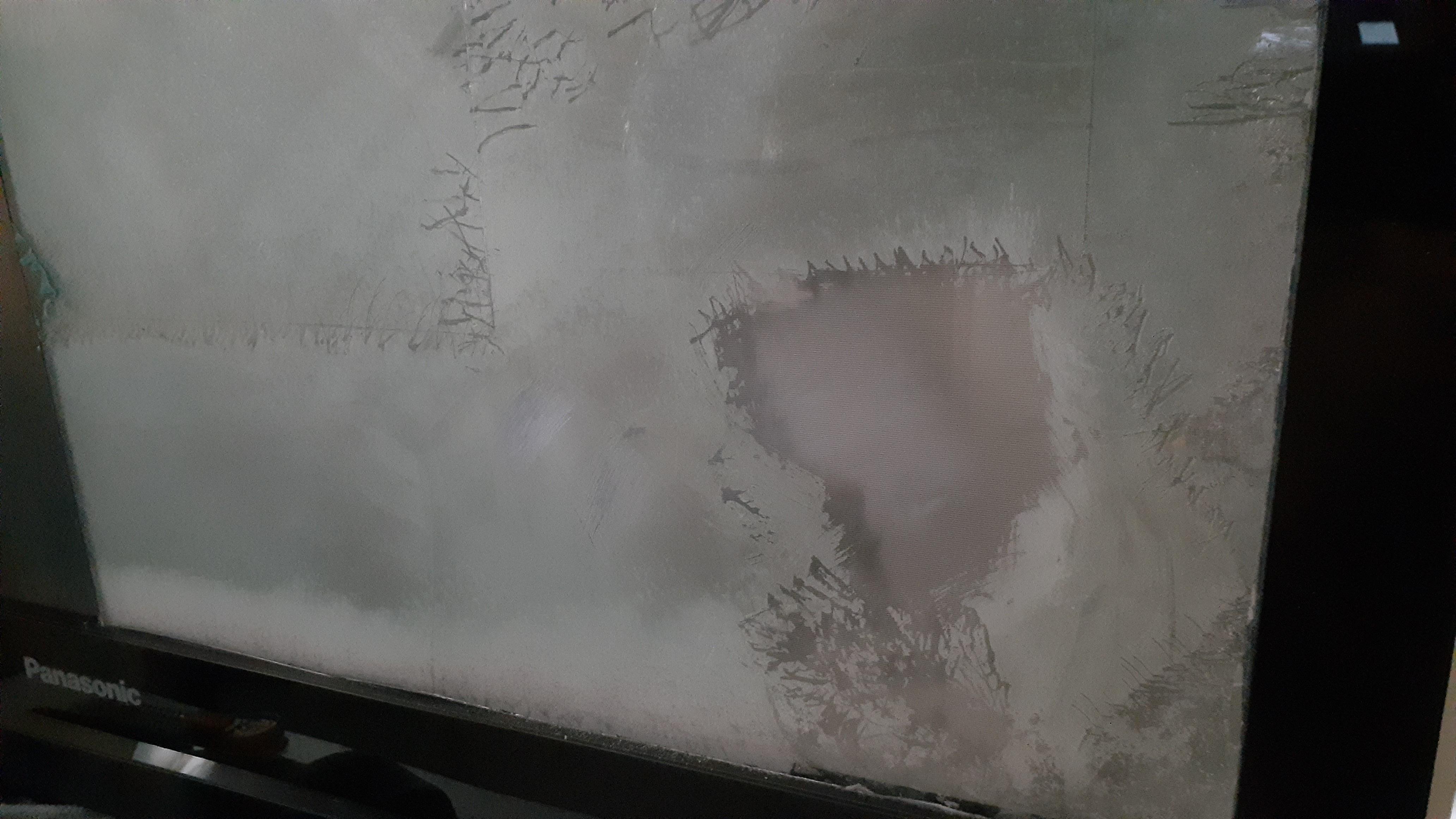

Now this is the worst part of the process: removing the plastic/rubber-like coating.At first I thought it was just glue, but it has shock absorbing properties, it even has little fibers. My guess is that it aids with panel strength. Anyways, in order to remove this layer more easily, lots of isopropyl alcohol and heat using a hairdryer (or maybe a heat gun) is necessary so it comes out cleanly, in single pulls.

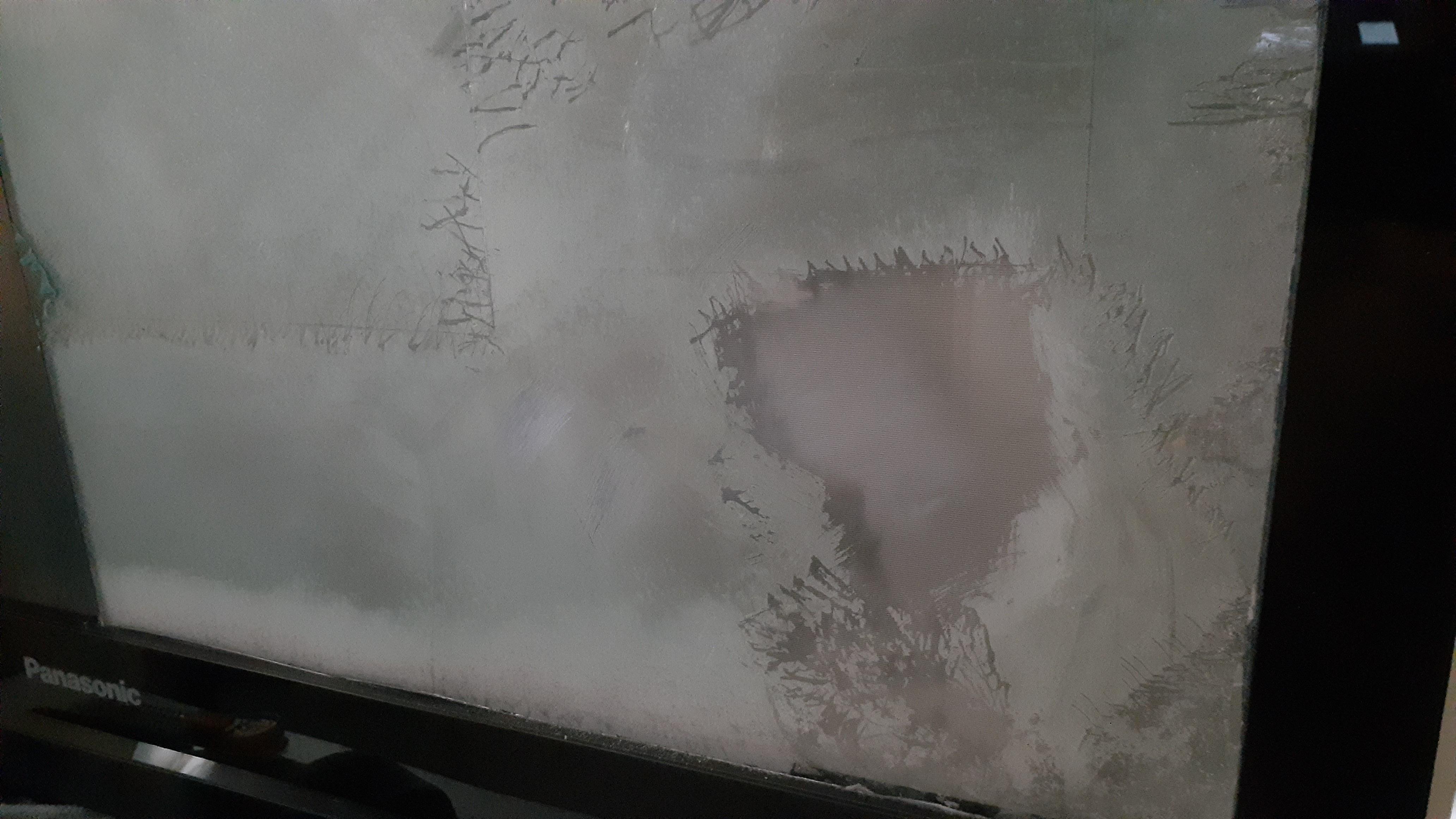

After removing both of those layers, we're left with the extremely hardened residual glue. Only steel wool and metal polish could do something to it, and even then it took me 2 hours to complete half of the panel.

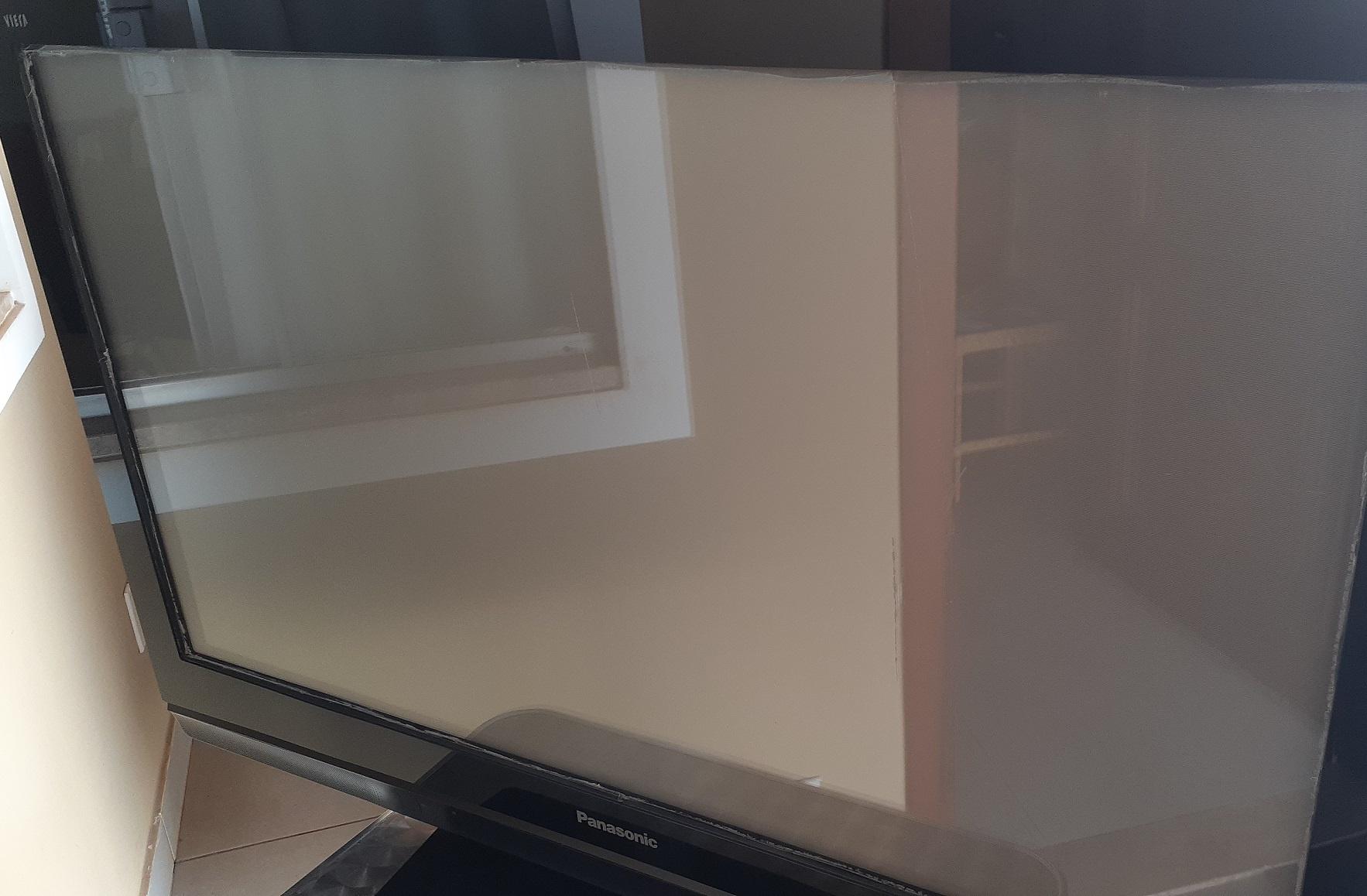

Here we can see the tint was caused by the plastic coating, likely victim of a strong chemical reaction. The unaffected parts of the screen are transparent, while the blue tinted ones are teal.

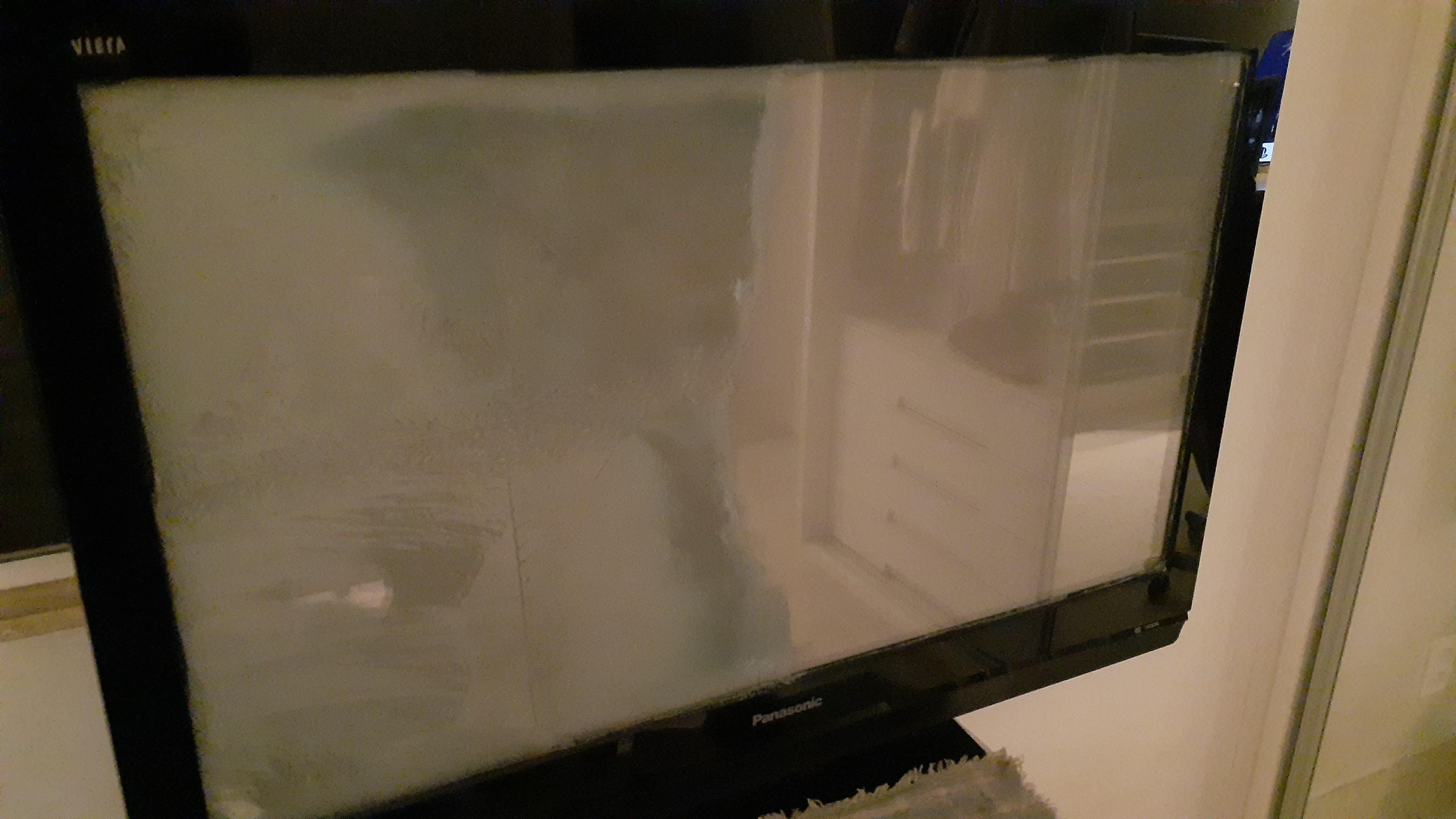

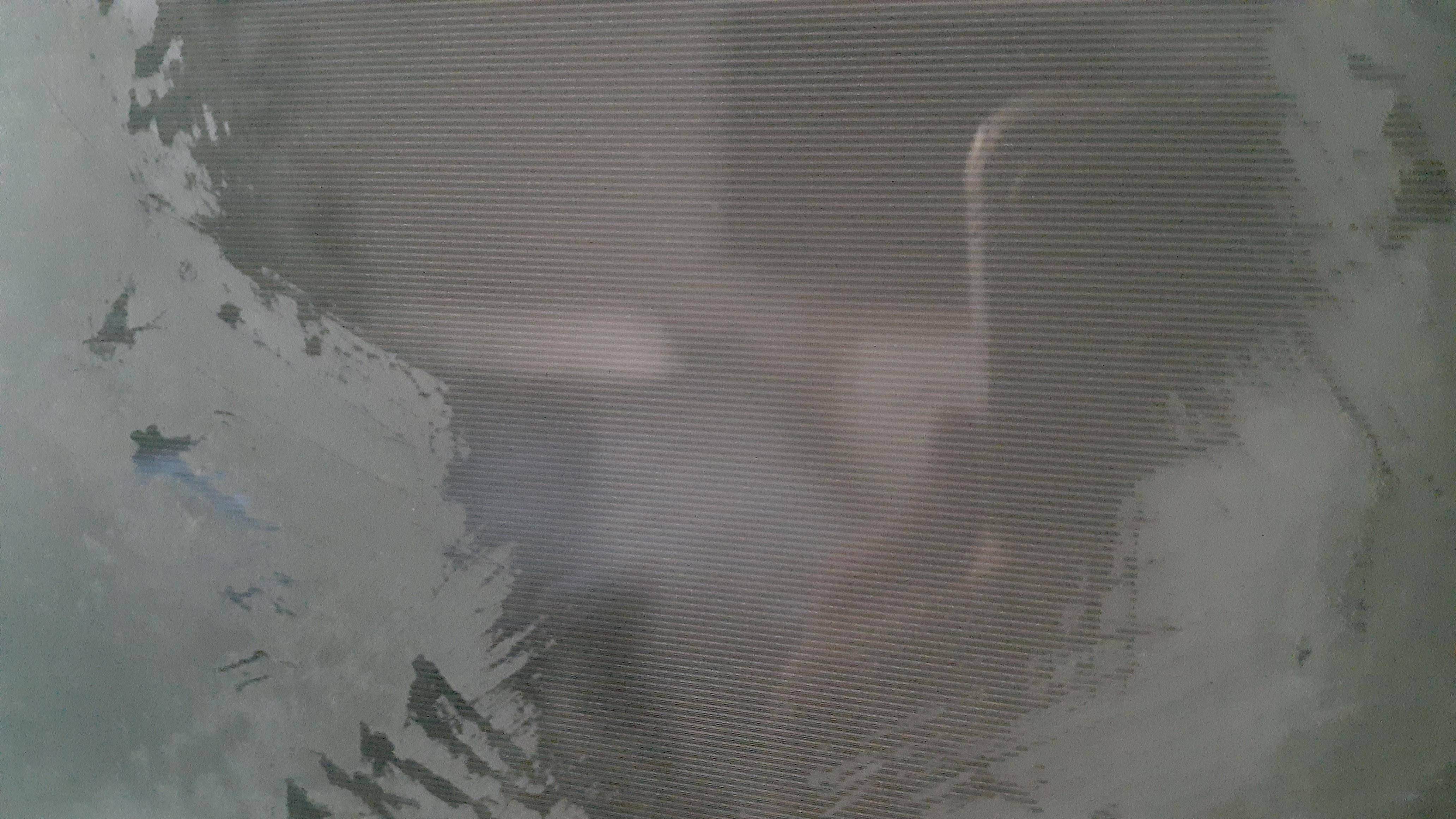

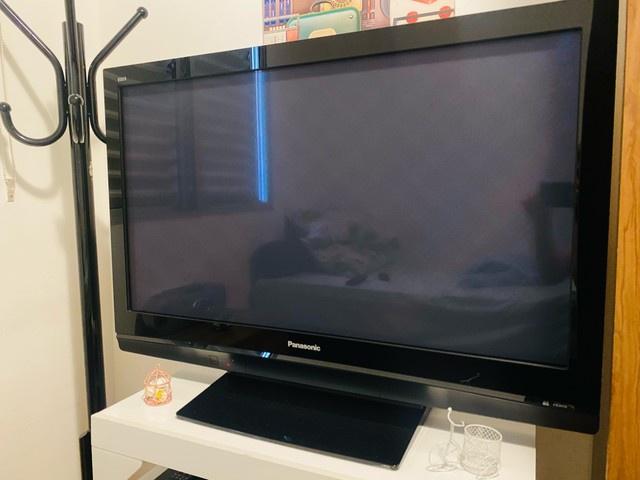

10 hours later, I now have an actual 42 inch mirror! Pictures and words cant convery how much work is required, I would never do this again... at least not without better equipment.

As a result, the screen is usable and I even noticed a significant brightness boost. The +65 Contrast setting had to be turned down to +25 for similar luminance level, without the coating. Black levels suffered because the tinted layer helps with that, but this Panasonic model in particular doesnt feature inky black levels anyways.

This only should be done if the coating is damaged beyond repair and finding a replacement isnt an option. If the coating is fine, leave it alone!

"Ok, that's probably just the anti-glare layer" - I thought. So using a microfiber cloth and automotive metal polish I was easily able to turn it into a nice mirror.

Unfortunately, the damage was beyond this layer and everything still had a horrible green tint. I initially wanted to completely remove the glass itself since it's not bonded to the PDP, but it had to stay due to potential structural issues.

It was time to go all out, nothing to lose here anyways. I cut the Front Glass using a box cuter and realized there were more layers above the actual glass.

It's a simple task but requires tons of elbow grease, patience and ability.

This is the tinted layer that enhances contrast/black levels and helps with colors, it's very similar to window tinted film. It comes out very easily.

Now this is the worst part of the process: removing the plastic/rubber-like coating.At first I thought it was just glue, but it has shock absorbing properties, it even has little fibers. My guess is that it aids with panel strength. Anyways, in order to remove this layer more easily, lots of isopropyl alcohol and heat using a hairdryer (or maybe a heat gun) is necessary so it comes out cleanly, in single pulls.

After removing both of those layers, we're left with the extremely hardened residual glue. Only steel wool and metal polish could do something to it, and even then it took me 2 hours to complete half of the panel.

Here we can see the tint was caused by the plastic coating, likely victim of a strong chemical reaction. The unaffected parts of the screen are transparent, while the blue tinted ones are teal.

10 hours later, I now have an actual 42 inch mirror! Pictures and words cant convery how much work is required, I would never do this again... at least not without better equipment.

As a result, the screen is usable and I even noticed a significant brightness boost. The +65 Contrast setting had to be turned down to +25 for similar luminance level, without the coating. Black levels suffered because the tinted layer helps with that, but this Panasonic model in particular doesnt feature inky black levels anyways.

This only should be done if the coating is damaged beyond repair and finding a replacement isnt an option. If the coating is fine, leave it alone!

Comment